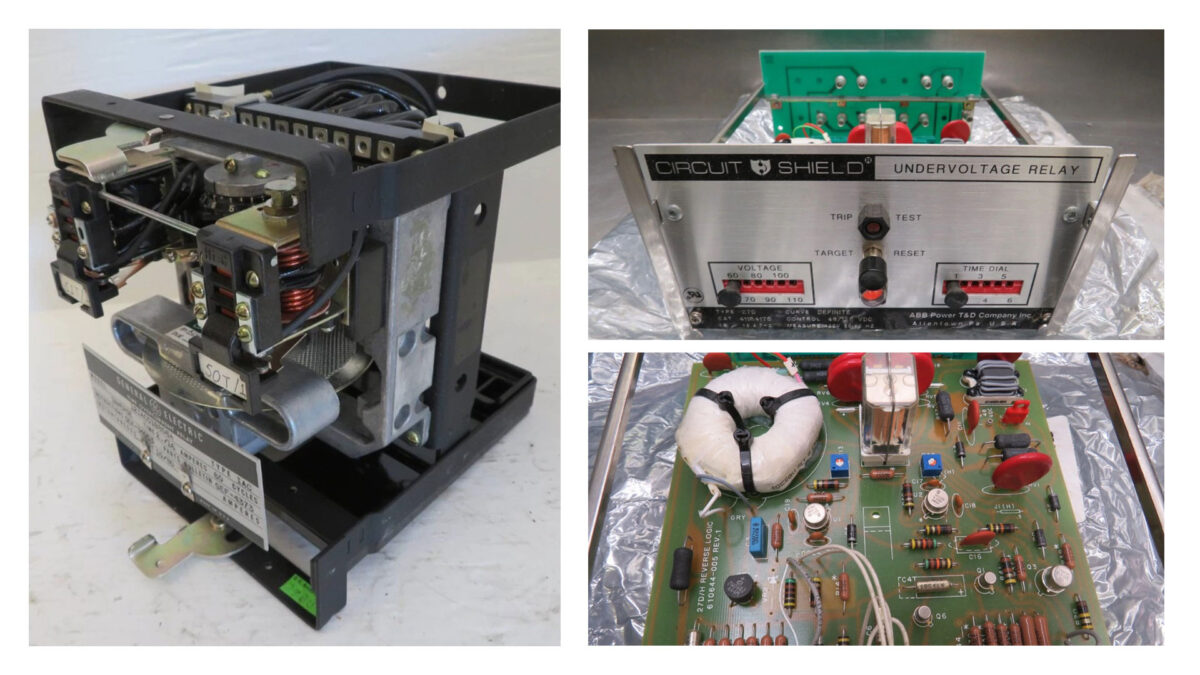

Protective relays are some of the most important components in an electrical power system. Their job is to detect faults and protect equipment from damage. Over time, both older electromechanical relays and newer solid-state or microprocessor-based relays can wear down or fail in ways that are specific to their design.

Understanding how these devices age (and how to properly maintain them) plays a key role in extending their lifespan and keeping your power system operating reliably.

Why Relay Testing Is Important

Older electromechanical and solid-state relays need regular attention to stay reliable. Electromechanical relays depend on moving parts, which can wear down or drift over time. As this happens, their performance can become less accurate, making periodic testing and re-calibration necessary to ensure they operate correctly.

Solid-state relays use electronic components, such as capacitors, that naturally degrade as they age. Temperature changes, electrical stress, and long periods of continuous operation can all contribute to this aging process. Without regular testing, these slow failures may not be obvious during normal operation and may only appear during a fault condition.

Maximizing Service Life

Mechanical relays, when properly maintained and tested, can last for decades. They are often easy to maintain and repair because replacement parts are still widely available. For this reason, it’s not uncommon to find mechanical relays in substations that have been in service well beyond their original life expectancy. However, this longevity does not mean they are superior to modern microprocessor-based relays.

Microprocessor-based relays offer many advantages that older relays simply can’t match, including advanced logic functions, better signal filtering, and built-in fault recording. Protection schemes can be adjusted through software rather than rewiring or changing hardware, making it much easier to adapt to changes in the electrical power system. These capabilities help improve overall system flexibility.

Aging of Microprocessor Relays

Like all equipment, microprocessor relays are not immune to aging. One of the most common causes of failure is the gradual drying out of electrolytic capacitors in the relay’s power supply. As these capacitors age, their electrical characteristics change, which can lead to unreliable operation or outright malfunction.

The lifespan of electrolytic capacitors is strongly influenced by temperature. Higher operating temperatures speed up the drying and breakdown of the electrolytic gel inside the capacitor. As the capacitor ages, its internal resistance (known as Equivalent Series Resistance or ESR) increases. This higher resistance generates more heat, which in turn accelerates the aging process even further.

On the other hand, very low temperatures can temporarily raise ESR as well, reducing the capacitor’s ability to filter electrical noise. Interestingly, this condition can sometimes be self-correcting. The extra heat generated by the increased resistance may help warm the capacitor back into its normal operating range, restoring more typical performance.

Practical Considerations for Relay Lifespan

Most utility relay panels are housed in climate-controlled buildings, which helps slow down temperature-related aging. Relays installed outdoors in enclosures, however, can be exposed to much higher temperatures (especially in hot climates) which can shorten their service life.

Microprocessor relays kept in controlled indoor environments can often function reliably for more than 16 years, with many still going strong past 20 years – well beyond the manufacturer’s designed lifespan. Outdoor relays, by contrast, typically don’t last as long because of the harsher temperature conditions they face.

Visual Inspections

Electromechanical and microprocessor relays should receive a monthly visual inspection. Look over the relays and their cases for any physical damage, and check for foreign objects or debris. For microprocessor units, make sure the relay is displaying the correct date and time.

Annual visual and mechanical checks should be more thorough. This includes cleaning and inspecting internal components such as disks and contacts, checking mounting hardware and connections for tightness, and verifying that any shorting devices are functioning properly. For microprocessor relays, also check for firmware updates or product recalls to ensure the unit remains up to date.

Frequency of Maintenance Tests

A full visual, mechanical, and electrical test should be performed every 24 months for electromechanical and solid-state relays, and every 36 months for microprocessor relays. These tests include everything from the regular inspections, plus functional checks of protection elements, control verification, insulation-resistance testing, and more.

This schedule assumes the equipment is in average condition and has medium reliability requirements, as defined in NETA-MTS 2023. Relays that are in poor condition or operate in critical environments may require more frequent testing to ensure reliable operation.

The specific condition of the equipment, its criticality, and the desired level of reliability all need to be considered when deciding on maintenance requirements. Combining industry standards with historical testing data and trend analysis helps create a strong, effective preventive maintenance program for electrical equipment.

Relay Lifespan and Maintenance in Focus

Mechanical relays, when properly maintained, can last for decades, while microprocessor relays provide advanced features but may age over time, especially in their electronic components like electrolytic capacitors. Understanding how temperature and environmental conditions affect relay life helps utilities make informed decisions about maintenance, capacitor replacement, or relay upgrades. By staying proactive, operators can keep their systems safe, reliable, and effective (even when faults occur).

You may also like...

- Data security tips for testing agencies and the clients they serve

- Bitcoin Mining and the Potential Energy Crisis

- Prolonging Transformer Service Life: 5 Key Factors to Consider

- Securing Test Data and Creating Immutable Trust with File Validation Over Blockchain

- Next-Generation Substation Technology: Centralized Protection and Control