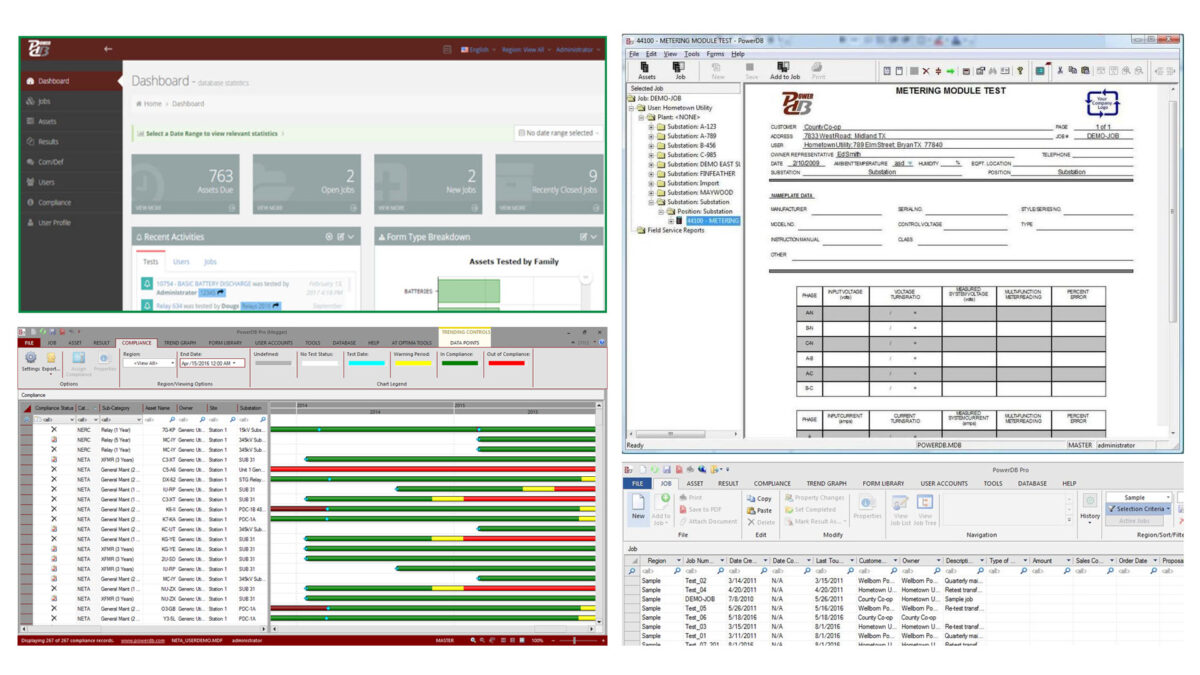

Data isn’t just numbers—it’s a roadmap for smarter decisions. Utilities and service providers generate large amounts of information every day, from equipment performance and maintenance logs to electrical test results. Keeping this data clean and well organized allows system operators to spot patterns, track equipment health, and take decisive action.

Data analysis can help predict equipment failures and support preventive maintenance planning. By tracking performance and identifying trends, asset managers can anticipate when equipment is likely to fail and schedule maintenance ahead of time.

This kind of analysis, however, depends on technicians entering data correctly. Modern test equipment can help reduce many clerical errors by automatically generating electronic reports instead of relying on someone to manually read and record values. Still, it only works if the technician sets up the equipment properly and knows how to review and validate the recorded data.

Turning Data Into Insights: Five Key Elements

When documenting tests and inspections for electrical systems, collecting accurate and reliable data is essential to keeping everything running smoothly. Precise data helps identify potential problems early, so they can be addressed quickly.

By understanding the value of quality data collection, technicians can better see why it’s important to keep test results clean and accurate. From boosting productivity to improving customer satisfaction and staying compliant with regulations, here are five key elements of quality data.

1. Attention to detail

Quality test data is fundamental to confirming that electrical equipment meets safety and efficiency standards. When conducting electrical tests, it’s important to follow the test procedure accurately while collecting clean and consistent data so the results are reliable and repeatable.

Clean data means information that’s free from errors or inconsistencies with attention to units and formatting. Measurements should be precise (to the appropriate decimal) and not influenced by outside factors that could skew the results. Ambient temperature and humidity conditions should be recorded, and test values corrected accordingly.

Consistent data means measurements are stable and uniform. Running the same test multiple times should produce similar results, showing that the equipment or system is reliable. Consistency reduces uncertainty and allows for confident, informed decisions based on the test results.

2. Efficiency

A well-maintained database allows for quick and easy retrieval of information. Consistent data also enables meaningful comparisons over time, helping identify real trends rather than anomalies caused by data entry errors.

To maintain a clean and efficient test results database, start by developing a clear data entry protocol for your organization. This protocol should outline the specific fields, units of measurement, and naming conventions to be used across all records. Personnel involved in data entry should be trained to understand and consistently follow these guidelines.

Using templates or forms with predefined fields helps minimize the risk of missing or incorrect information. Drop-down menus or selection lists can further improve consistency across entries.

Consider adding controls that hide blank or non-applicable fields in electronic test forms. This can reduce confusion for both technicians and end users.

Implement version control to track changes and updates over time. Proper indexing and logical organization of data will improve retrieval speed. In addition, consider setting up automated processes for data validation and regular backups to help prevent data loss.

3. Compliance

Following regulatory requirements is essential. These rules exist to ensure power systems are safe, reliable, and efficient. Adhering to them also demonstrates that service providers are professional and committed to quality work.

Compliance is especially important when it comes to safety. Electrical systems can be dangerous if not properly maintained, and following regulations helps prevent incidents such as electric shock and arc flash. Industry standards outline safe work practices, proper equipment use, and protective measures designed to keep everyone safe.

Staying compliant also supports system reliability. Regular testing and maintenance help identify potential issues before they become serious problems, reducing the risk of unexpected failures or outages. This is essential in places like hospitals, data centers, or industrial plants, where keeping power running smoothly is a must.

Related: Demystifying NFPA 70B and NETA MTS: Which Guide Aligns with Your Electrical Maintenance Needs?

4. Customer satisfaction

Providing customers with accurate and reliable test data is key to earning their trust. Clear, well-organized reports that are easy to understand help build strong, positive relationships between service providers and their clients.

A well-maintained database makes historical analysis and trend tracking effortless, adding value for service providers. Reports can be generated to meet client-specific requirements without much extra effort, further enhancing overall customer satisfaction.

5. Future reference

Keeping clean and consistent maintenance records helps system operators understand how equipment performs over time. This historical data makes it easier to track changes, identify trends, and make informed decisions about repairs or replacements.

A well-maintained database also streamlines data entry during routine maintenance. Nameplate information can be prepopulated and verified rather than re-entered each cycle, and historical test data can be imported and reviewed for immediate comparison.

Summary

Clean and accurate test data is essential in electrical testing and maintenance. It forms the foundation for reliable, efficient, and effective operations across the industry. By spotting trends over time, technicians can prevent unplanned outages and reduce maintenance costs.

Periodic testing is a powerful tool for smarter decision-making. It can identify energy-hungry equipment, monitor asset health, and track how assets are being used. This information supports better budget planning and ensures equipment is replaced or upgraded at the right time.

Actionable data also makes it possible to perform equipment audits, track warranties, and provide personalized services that benefit clients. By turning raw data into insights, asset owners can make smarter decisions, while service providers strengthen customer trust and boost productivity.

You may also like...

- Optimizing Infrared Scans: 5 Key Elements for Comprehensive Reporting

- Why insulation resistance trending may be your best predictor of electrical failure

- When Replacement Takes Years: Proven Strategies for Transformer Longevity

- Improving Cybersecurity in the Electrical Power Distribution Industry with Blockchain

- Infrared Insights: The Path to Preventing Electrical Failure with IR Technology