The rapid growth of data centers is driving electricity use to record levels and putting increasing pressure on the U.S. power grid. These facilities are critical for supporting technologies like artificial intelligence, cryptocurrency mining, and cloud computing – but they also demand enormous amounts of power.

At the same time, much of the nation’s electrical infrastructure is aging. More than 70% of the U.S. power grid is over 25 years old, making upgrades and modernization more urgent than ever. As new data centers come online and utilities work to strengthen their systems, demand for electrical equipment is rising sharply.

Adding to the challenge, the U.S. is facing a serious shortage of large power transformers. In many cases, delivery times now stretch three to five years. This shortage is driven by limited domestic manufacturing capacity, growing global demand, and trade-related constraints.

Together, rapid power expansion and long replacement timelines mean existing transformers must be protected and maintained more carefully than ever. Replacing failed equipment is no longer quick or easy, so asset owners need to take a more proactive approach.

By combining continuous online monitoring with disciplined inspection and maintenance testing, asset owners can extend the life of their transformers and identify potential problems before they lead to failure. This approach helps prevent unplanned outages and avoid costly downtime.

In this article, we explore condition-based strategies and diagnostic tools that can help reduce risk and support data-driven decisions about when to repair, refurbish, or plan for equipment replacement.

Online Monitoring: An Early Warning System for Failure

Online condition monitoring and advanced diagnostic tools help asset owners focus their limited time and resources where they matter most. One of the biggest advantages of online monitoring is its ability to uncover problems that may not be visible during routine inspections or scheduled testing. Instead of relying on snapshots in time, online systems provide continuous insight into equipment health.

Related: Monitoring the Condition of Power Systems with Non-Destructive Test Techniques

Dissolved Gas Analysis (DGA)

Dissolved gas analysis is often the earliest indicator that something is going wrong inside a transformer. As insulation and oil begin to deteriorate, gases are released into the oil. By identifying and tracking these gases, it is possible to detect issues such as overheating, hot spots, insulation breakdown, partial discharge, and arcing – often long before a failure occurs.

Because DGA is usually the first sign of trouble, increasing the frequency of testing is essential. Online DGA monitoring allows asset owners to continuously track gas levels inside the transformer’s main tank, providing real-time visibility instead of waiting weeks or months between manual samples.

There are two common approaches to online gas monitoring. Key gas monitoring is a more economical option that focuses primarily on hydrogen, which is a strong general indicator of abnormal activity. This approach allows broader coverage across many assets.

Multi-gas monitoring, while more expensive, tracks several gases (sometimes up to nine) and provides a much more detailed picture of transformer condition. This level of monitoring is best suited for critical transformers or those operating under heavy or highly variable loads.

Partial Discharge Monitoring

Partial discharge (PD) is another early warning sign of insulation degradation. It occurs at weak points such as small voids, cracks, or impurities within the insulation, where electrical stress exceeds the insulation’s strength. These defects often develop due to aging, contamination, or manufacturing imperfections.

Online partial discharge monitoring is a non-destructive and non-invasive predictive maintenance tool. It measures discharge activity while the transformer is operating under normal voltage conditions. With the right sensors in place, PD activity can be continuously monitored and trended over time, allowing technicians to identify worsening conditions well before they lead to major damage or failure.

Infrared Scanning

Thermal imaging is a fast and effective way to inspect electrical equipment without making physical contact. Because inspections can be performed while equipment remains in service, there is no need for shutdowns. By comparing similar components, abnormal temperature patterns can be quickly identified.

One of the strengths of infrared scanning is that images do not need to be fully interpreted to be useful. Elevated temperatures alone can signal that further investigation is needed, making infrared imaging an excellent troubleshooting tool.

Infrared cameras do not rely on visible light, which makes them well suited for use inside electrical enclosures. Fixed micro-sensors and wide-angle cameras can be permanently installed at critical points and accessed remotely at any time. Software platforms can automatically detect abnormal temperature increases and trigger alarms when preset thresholds are exceeded.

Related: Infrared Insights: The Path to Preventing Electrical Failure with IR Technology

Electrical Tests: Digging Deeper and Identifying Trends

While online monitoring provides early warnings, periodic electrical testing allows asset owners to dig deeper and confirm developing issues. These tests help identify long-term trends, verify insulation condition, and uncover problems that may not yet be severe enough to trigger alarms.

Related: Prolonging Transformer Service Life: 5 Key Factors to Consider

Power Factor Testing

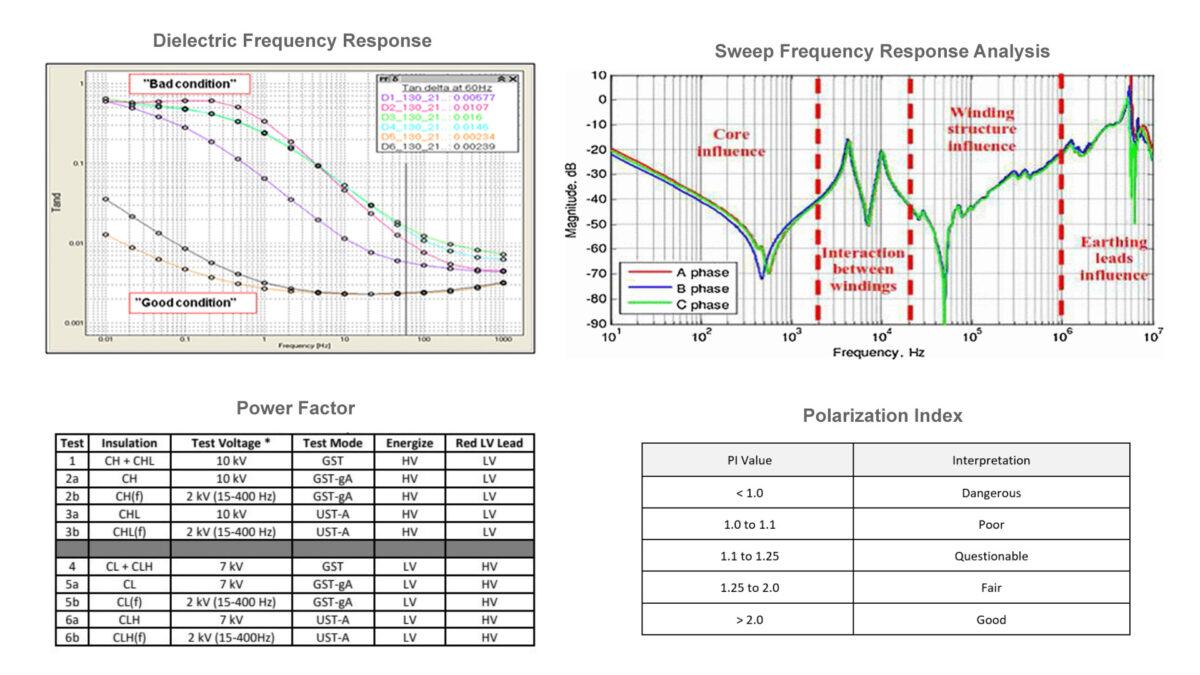

Power factor testing evaluates the overall health of a transformer’s insulation system, including windings, bushings, and insulating oil. It works by measuring electrical losses in the insulation, which can reveal hidden problems such as moisture intrusion, contamination, or aging materials.

This test provides a clear, numerical indication of insulation quality and can detect issues like carbon tracking or partial discharge that may not show up in simpler tests. For example, basic DC tests such as insulation resistance can sometimes appear normal because surface layers mask deeper problems. Power factor testing offers a more complete and reliable picture.

Tracking power factor or dissipation factor results over time is especially valuable. Trending these results helps plan maintenance activities (such as oil processing or insulation drying) before conditions worsen and lead to failure.

Sweep Frequency Response Analysis (SFRA)

A transformer’s internal mechanical structure can change over time. One common issue is movement or loosening of the windings, which can occur due to short-circuits, seismic forces, and aging. Even small shifts can place additional stress on insulation materials, accelerating their degradation and increasing the risk of electrical faults.

SFRA is used to detect these mechanical changes. The test sends electrical signals through the transformer windings across a wide range of frequencies and measures how the transformer responds. These results are then compared to baseline measurements taken when the transformer was known to be in good condition.

Significant changes in the frequency response can indicate winding movement or deformation, allowing corrective action to be planned before serious damage occurs.

Dielectric Frequency Response (DFR)

Moisture is one of the most damaging contaminants in transformer insulation. When moisture is present, it alters the electrical properties of the insulation system, affecting how it stores and resists electrical energy.

DFR testing detects these changes by measuring the insulation’s response across a range of frequencies, typically from very low frequencies up to several kilohertz. The results are compared against reference data or industry standards to assess insulation condition.

Dielectric Frequency Response testing is particularly effective at identifying the presence and severity of moisture within solid insulation, helping asset owners decide whether drying, oil treatment, or other corrective actions are needed.

Other Important Tests and Inspections

Additional tests such as winding resistance, turns ratio (TTR), and polarization index are commonly used to evaluate mechanical connections, confirm proper voltage ratios, and assess insulation quality.

Regular visual inspections also play an essential role in extending transformer life. Devices such as temperature and oil level indicators, pressure-relief devices, gas accumulators, and fault-pressure relays should be routinely checked and verified to ensure they are operating correctly.

How Often Should Transformers Be Tested?

Regular testing and inspection is critical to condition assessment, but testing frequency should be matched to the size, condition, and importance of the equipment.

For large dry-type and liquid-filled transformers, basic visual inspections should be performed monthly. These inspections typically look for obvious issues such as oil leaks, abnormal noise, overheating, or damaged components. Smaller dry-type transformers generally require less frequent attention and can be visually inspected every other month.

More detailed visual and mechanical inspections should be performed annually for all transformers, regardless of size. These inspections go beyond surface checks and focus on mechanical integrity, connections, cooling systems, and protective devices.

In addition, a full visual, mechanical, and electrical testing program should be conducted on a regular cycle. For large dry-type and liquid-filled transformers, this comprehensive testing is typically recommended every 24 months. Smaller dry-type transformers can usually be tested every 36 months.

These recommended intervals are based on equipment that is in average condition and has medium reliability requirements, as defined by NETA Maintenance Testing Specifications (NETA-MTS 2023). Transformers that are older, in poor condition, heavily loaded, or located in critical applications may require more frequent inspections and testing to maintain reliability.

Ultimately, testing frequency should be determined by a combination of factors, including equipment condition, operational importance, and acceptable risk level. Using industry standards alongside historical test results and trend analysis allows asset owners to build a preventive maintenance program that is both effective and cost-efficient.

Data Analysis: Putting It All Together

Testing and monitoring programs generate large amounts of data over time, but that data is only valuable if it is clean, accurate, and well organized. Consistent maintenance records are essential for understanding how equipment performs and ages year after year.

Related: How Accurate Test Results Drive Smarter Electrical Operations

When historical data is properly maintained, it becomes much easier to spot changes, identify long-term trends, and make informed decisions about when repairs, refurbishment, or replacement may be needed. Even simple tools can be effective as most modern spreadsheet programs make organizing and charting data straightforward. Common options include Google Sheets, LibreOffice Calc, and Microsoft Excel.

By tracking results over time, asset owners can see which transformers are beginning to drift out of normal operating ranges or degrade faster than similar equipment in the same facility. These trends often provide early warning signs that are not obvious from a single test result.

One of the most important factors in meaningful data analysis is consistency. Test methods must remain the same from one test cycle to the next, and measured results should be corrected for temperature where applicable. Without consistent procedures and proper corrections, trend data can be misleading and lose much of its value.

Bonus Consideration: Physical Guards

In addition to electrical and mechanical risks, transformer owners must also consider physical threats. Natural disasters, vandalism, and intentional attacks can all damage critical equipment and lead to extended outages. Physical protection measures can significantly reduce these risks.

Concrete Walls

Replacing simple chain-link fencing with solid concrete or cinder block walls provides a much higher level of protection. These structures help deter unauthorized access and offer resistance against long-range ballistic threats. They also make it far more difficult for intruders to reach sensitive transformer components.

Obfuscation and Concealment

Transformers can be concealed to reduce visibility and attract less attention. Substation equipment can be enclosed within structures that resemble small buildings or homes. In other cases, transformers may be positioned alongside railways, under freeways, or in other less conspicuous locations. Reducing visibility lowers the likelihood of both vandalism and targeted attacks.

Shielding and Armor

Kevlar is a lightweight, bullet-resistant material commonly associated with body armor, but it is also used to protect critical infrastructure. Because it is relatively light, Kevlar shielding can be installed with minimal structural impact and without major modifications to existing equipment.

Manufacturers now offer ballistic panels and shielding systems designed specifically for substations and transformers. These systems can be installed around critical components to reduce damage from physical attacks. Additional options include hardened steel panels and specialized protective coatings that further improve resistance and durability.

Related: Protecting Critical Electrical Infrastructure from Attack

Transformer Care in a Time of Shortages and High Demand

The rapid growth of data centers, combined with aging infrastructure and long equipment replacement timelines, has made transformer reliability more critical than ever. With power demand rising and new transformers taking years to procure, asset owners can no longer afford a reactive approach to maintenance. Protecting and extending the life of existing equipment is now a necessity, not an option.

Online monitoring plays a vital role in detecting problems early, often before visible symptoms appear. Technologies such as dissolved gas analysis, partial discharge monitoring, and infrared scanning provide continuous insight into transformer health and allow issues to be identified while they are still manageable. When paired with periodic electrical testing (such as power factor, SFRA, and DFR) asset owners gain a deeper understanding of insulation condition, mechanical integrity, and moisture levels.

Equally important is how test and monitoring data is managed. Clean, consistent, and well-organized records make it possible to identify trends, compare similar equipment, and make informed, data-driven decisions. Following industry-recommended testing intervals, maintaining consistent test procedures, and trending temperature-corrected results help create a preventive maintenance program that reduces risk and avoids unplanned outages.

Finally, electrical health is only part of the reliability picture. Physical protection measures such as concrete barriers, concealment, and ballistic shielding add an additional layer of defense against natural disasters and physical threats.

You may also like...

- Demystifying NFPA 70B and NETA MTS: Which Guide Aligns with Your Electrical Maintenance Needs?

- Dry Ice Blasting: Next-Generation Cleaning Techniques for Electrical Distribution

- The Lifecycle of Protective Relays: Aging and Maintenance Insights

- Layer by Layer: Breaking Down Virtual Protection Relay Architecture

- How Accurate Test Results Drive Smarter Electrical Operations